Titanium as a Material: Decorative Titanium ~ Vol. 3~

- Product

- titanium

※)The content of this article reflects our opinion and does not guarantee completeness or accuracy. When purchasing or processing products, please consult with specialized professionals, including our company, and verify the material based on its intended purpose and application before use.

In Vol. 1, we discussed titanium in general, and in Vol. 2, we explored titanium processing techniques. However, many of the topics were highly specialized and included applications that are not widely known to the general public. In this issue, we’ll focus on decorative titanium used in more familiar, everyday settings.

At Nippon Steel, this decorative titanium product is being marketed under the name TranTixxii®.

TranTixxii® is the original brand name for decorative titanium and is a registered trademark of Nippon Steel. The logo and its meaning are as follows.

Figure 2. TranTixxii® Naming Concept (Referenced from Nippon Steel Website No. 2)

As a material, I believe it possesses an artistic coloration that sets it apart from conventional metal materials such as steel sheets.

Traditional metal materials—such as gold, silver, copper, and stainless steel—have their own inherent metallic colors, but few have offered a truly diverse range of colors within the material itself.

The inherent color of a metal is determined by the wavelengths of light it most readily reflects.

- Copper appears its characteristic color because it readily reflects light with wavelengths longer than 600 nm, such as orange and red.

- Gold readily reflects light with wavelengths longer than 550 nm, so in addition to copper’s orange and red hues, it also reflects yellow-green and yellow light—resulting in its distinctive golden appearance.

- Silver reflects all wavelengths of visible light at a high rate, resulting in a lack of coloration. Stainless steel and iron also appear silver in color.

Returning to titanium, although it normally appears silver like stainless steel, it can produce various colors by controlling the thickness of a colorless, transparent oxide film (TiO₂) formed on its surface. This is based on the same principle that gives soap bubbles and rainbows their visible colors.

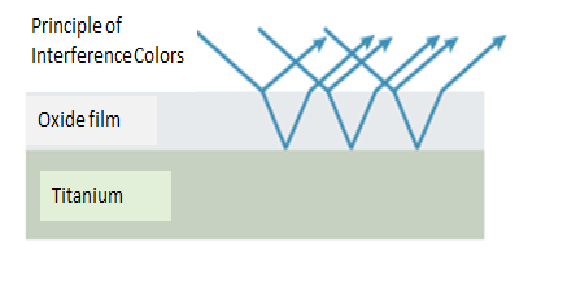

As schematically illustrated in Figure 3, the wavelengths of light reflected from the surface of the oxide film and those reflected from the underlying titanium surface either reinforce or cancel each other out depending on their phase relationship. This interference effect varies with the film’s thickness, resulting in the appearance of different colors.

- Colors that appear due to interference of wavelengths are called interference colors. Alternatively, when colors are produced by microscopic structures such as surface irregularities or film layers, they are referred to as structural colors

The control of film thickness is carried out using a technique called anodizing. In this method, titanium is used as the anode in a conductive electrolyte solution, and the thickness of the oxide film is adjusted by manipulating factors such as voltage, current, temperature, and duration.

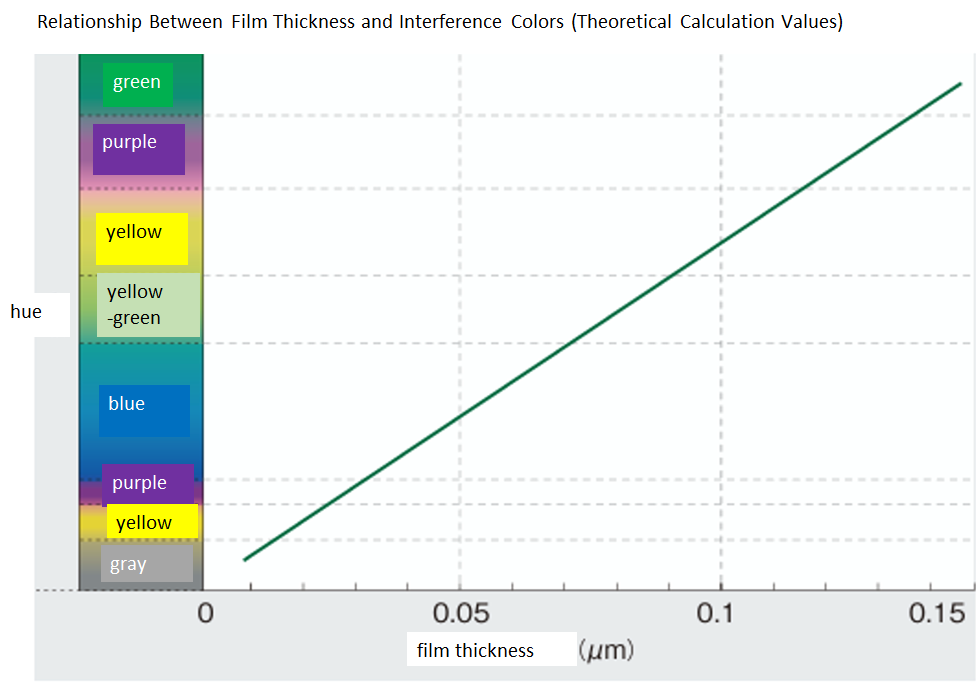

As shown in Figure 4, there is a correlation between the thickness of the oxide film and the resulting color. Starting from thinner films, the colors transition through gray, yellow, purple, blue, yellow-green, yellow, purple, and green. It is believed that red may also be achievable with even thicker films, although this has not yet been realized.

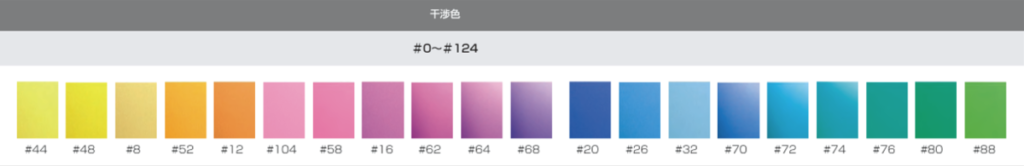

The soft hues—such as pale yellow, purple, blue, and green—depicted in Figure 5 evoke a sense of natural tranquility and do not convey the coldness typically associated with metal. They invite one to reach out and touch them. Unlike painted finishes applied to steel, these delicate shades are created through the reflection of light, evoking a world of refined aesthetic expression. Moreover, because the coloration does not rely on paint, it exhibits minimal fading over time and offers an environmentally friendly material choice.

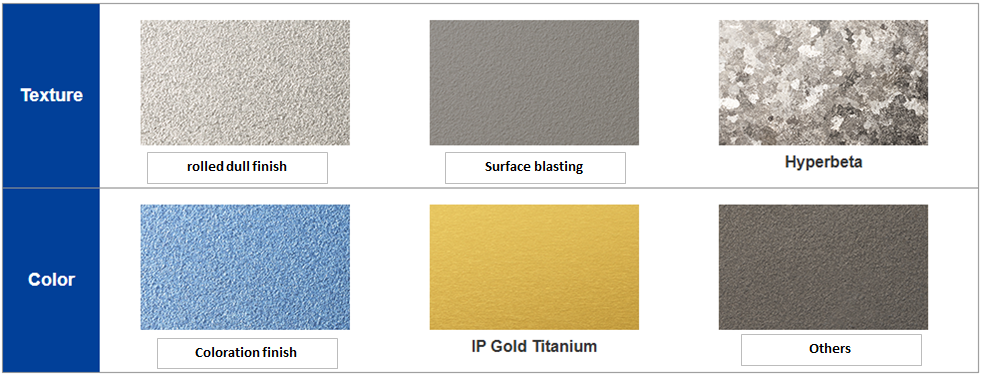

While interference colors can produce hues close to gold, a more vivid golden appearance can be achieved by depositing titanium nitride (TiN) onto the titanium surface using a method called ion plating. This technique yields the rich golden tone shown in Photo 1, making it particularly striking for use in shrines and temples.

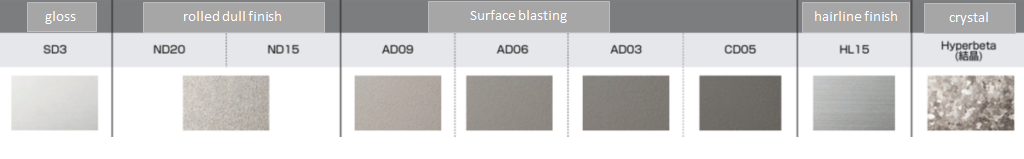

In addition to these colors, various textures and finishes can be achieved through combinations such as polishing the titanium surface to a smooth, glossy state; applying a matte finish known as ‘dull finish’ with a pear-skin texture; or heat-treating the material to coarsen its crystal structure. (See Photo 2)

A wide variety of beautiful finishes can be achieved through combinations of base textures and colors—Photo 3 shows just a small selection. This material allows for strong individual expression and, in today’s terms, might even be called a ‘cool’ material.

The applicable plate thickness ranges from 0.3 to 2 mm, and it may be regarded as a premium-grade material—perhaps even considered a form of art. Naturally, the cost is a point of concern, but given its virtually everlasting durability, a modest price increase seems justifiable. It is also likely to be well received as a gift.

Since the material itself is titanium, its corrosion resistance is, of course, unquestionable. In addition, its low thermal expansion results in minimal deformation due to heat, and its low thermal conductivity makes it highly effective as an insulating or heat-retaining material.

Tumblers (Photo 4) and bottles that take advantage of titanium’s heat retention properties have been developed, along with a variety of other applications. Even in residential settings, titanium demonstrates both its corrosion resistance and aesthetic appeal when used in exterior and interior elements such as nameplates, signage, entrances, bar counters, and kitchens.

If there’s anything else you’re looking for, please don’t hesitate to let us know.

- In addition to tumblers (Photo 4) and bottles that make use of titanium’s heat retention capabilities, a wide range of other applications have been developed. Even in residential environments, titanium demonstrates both its corrosion resistance and aesthetic value when used in exterior and interior materials, such as nameplates, signage, entrances, bar counters, and kitchen surfaces.

Titanium has already been widely used in roofing and exterior materials for shrines and temples, as well as interior wall panels and as a substitute for wood. Rather than vibrant rainbow-like colors, finishes that resemble verdigris or retain the natural silver tone with a blasted surface can be selected to suit the specific application, creating an appropriate and refined aesthetic. (Photo 5)

- There is no concern of corrosion even in coastal areas. Titanium has been widely used in seaside facilities such as the spherical observation deck of the Fuji TV headquarters and the Port of Nagoya Public Aquarium.

As demonstrated, decorative titanium can be applied across a wide range of products—from everyday items to more majestic structures—and its potential continues to grow. If you have any ideas for new applications, we would be delighted to hear from you.

In preparing this article, we referred to the website of Nippon Steel (Website 2) listed below, and many of the figures and photographs have been published with permission from Nippon Steel Corporation. We would like to express our sincere gratitude.

We hope you will also take a look at the following Nippon Steel catalogs and develop a greater interest in titanium.

“Our company is…”

We are a specialized trading company based in Japan, dealing in high-tensile steel and other special steels.

Please feel free to contact us.

Feel free to email us.

↓↓↓

info@kumagai-steel.co.jp