Advantages of Wear-Resistant Steel (ABREX®) Vol.1 ~ Hardness Levels and Toughness ~

- Product

- ABREX

※)The content of this article reflects our views and is not guaranteed in its entirety. When purchasing or processing products, please consult with our company and other specialized professionals, and conduct appropriate verification based on the intended purpose and application before using the relevant material.

This blog is provided by Kumagai Speciality Steel, a specialist in special steels. It shares information about Japan’s high-performance steel materials in an easy-to-understand format, based on fundamental knowledge of special steels. Updates are made irregularly.

Table of Contents

・What is wear-resistant steel?

・How hard is wear-resistant steel?

・Hardness levels of wear-resistant steel

・Toughness of wear-resistant steel

What is wear-resistant steel?

It is literally steel that resists wear. Wear occurs where objects rub against each other.

Bulldozers dealing with soil and rocks, dump truck beds, hydraulic excavator and wheel loader buckets, conveyor chutes and hoppers, crusher blades, unloader grab buckets, pulverizers… Wear occurs everywhere.

Worn parts need to be replaced or repaired, but this incurs costs and results in downtime. Therefore, minimizing wear is crucial.

The efficient solution is to use wear-resistant steel, which has high resistance to abrasion. Since wear-resistant steel can be welded, it is possible to partially repair heavily worn areas by overlaying it onto general steel materials.

In addition to wear-resistant steel, there are other materials with high wear resistance, such as ceramics and hard surfacing. The choice depends on factors such as usability and cost-effectiveness.

So, why does wear-resistant steel experience less wear? It is because the hardness of the steel material has been increased.

Generally, hardness and wear resistance are correlated—the harder the material, the less wear it experiences. A diamond can easily scratch glass (meaning it removes material), whereas ordinary steel is much more difficult to scratch. When materials of differing hardness come into contact, the softer one tends to sustain more damage.

Wear-resistant steel is hardened to a level close to that of glass through its chemical composition and heat treatment. Steel becomes harder when subjected to a heat treatment process called quenching. In addition to increased hardness, it retains its toughness and resistance to cracking.

How hard is wear-resistant steel?

As an indicator of hardness, depending on the testing method,

・Vickers hardness

・Rockwell hardness

・Brinell hardness

・Shore hardness

These are some of the common methods. In wear-resistant steel, hardness is typically expressed using ‘Brinell hardness’.

The standard Brinell hardness test determines hardness by pressing a 10 mm diameter tungsten carbide ball into the steel with a force of 3 tons and measuring the diameter of the indentation left on the material. The harder the steel, the less it is indented, resulting in a smaller indentation.

Cemented carbide is made by bonding tungsten carbide (WC) with cobalt (Co). Tungsten carbide itself is said to be the second hardest material after diamond. A 10 mm ball that remains unscathed even under 3 tons of force—now that’s impressive!

The hardness conversion values were previously included as a reference in the JIS Handbook – Iron and Steel I, a standard for industrial products in Japan, but they have been removed in recent years. Originally, these values were cited from SAE J417, an American automotive industry standard. Currently, they can also be found in ISO 18625. I would like to include them here, but due to copyright issues, I have omitted them.

Hardness levels of wear-resistant steel

The hardness levels of wear-resistant steel are specified by different manufacturers, with Brinell hardness classes such as 400, 450, and 500.

The wear-resistant steel mainly handled by our company, manufactured by Nippon Steel, includes the following base standards:

- ABREX®400

- ABREX®450 (currently difficult to obtain)

- ABREX®500

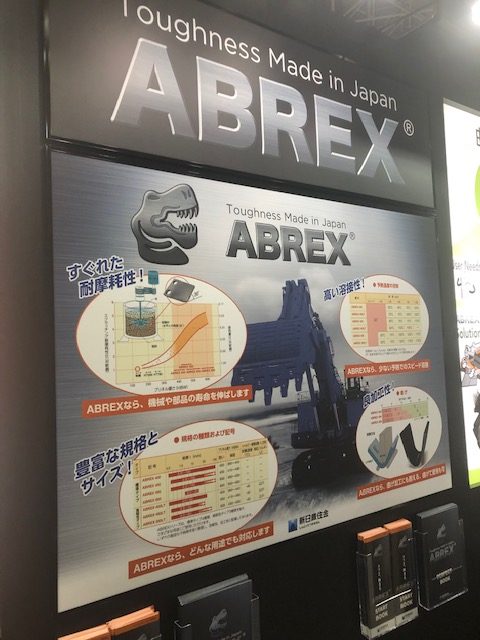

Nippon Steel had been manufacturing and selling wear-resistant steel ahead of the global market since the 1960s, before the establishment of the former Nippon Steel Corporation. In 2012, when Nippon Steel and Sumitomo Metal merged, the brand name was updated to ABREX®. (ABREX is a registered trademark of Nippon Steel Corporation.)

Our exhibition panel

In Vickers hardness testing, which measures hardness by pressing a diamond onto the surface, the 400, 450, and 500 classes correspond to approximately 420, 480, and 530, respectively. Ordinary glass is said to be around 550.

Compared to other steel materials, 50-kilogram steel has a Brinell hardness of around 150, while 80-kilogram steel is approximately 240. Wear-resistant steel has a significantly higher hardness level than these. It is understandable that it offers several times the wear resistance of ordinary steel.

Toughness of wear-resistant steel

Generally, as hardness increases, toughness tends to decrease, making the material more brittle.

Even so, according to the catalogs of various manufacturers, wear-resistant steel possesses a reasonable level of toughness. For use in extremely cold environments, a high-toughness type with guaranteed low-temperature toughness is required, but generally, the standard type is sufficient.

When a straight scratch is made on glass with a diamond, that area easily breaks. This is because glass has very low toughness.

Steel has a certain level of toughness, so it does not break easily. However, if a crack is present and a strong impact is applied, it is not completely immune to breaking.

In terms of actual absorbed energy, welded structural steel has a standard guarantee requirement of at least 27J, but actual values often exceed 100J by a significant margin. On the other hand, according to various manufacturers’ catalogs, wear-resistant steel typically has values of around 30–60J. However, it seems that fractures caused by low base material toughness are not frequently observed.

| Brinell hardness | Vickers hardness | Toughness | Price | |

| Equivalent to 50-kilogram high-tensile steel | 150 | 165 | ◎ | ◎ |

| Equivalent to 80-kilogram high-tensile steel | 240 | 250 | ◎ | 〇 |

| Wear-resistant steel (HB400) | 400 | 420 | 〇 | 〇 |

| Wear-resistant steel (HB450) | 450 | 480 | 〇 | 〇 |

| Wear-resistant steel (HB500) | 500 | 530 | 〇 | 〇 |

| Glass | 550 | xxx | 〇 | |

| High-speed steel (HSS) | 900 | x | x | |

| Cemented carbide” | 1800 | xx | xx |

In this presentation, we introduced an overview of wear-resistant steel (Nippon Steel’s brand name ABREX®), including its applications, hardness, and toughness.

Next time(vol.2), we plan to explain how wear-resistant steel is made and discuss important considerations when using it.

Additionally, we will share useful information on processing ‘extremely hard wear-resistant steel,’ including cutting, welding, bending, and tool-related know-how.

“Our company is…”

We are a specialized trading company based in Japan, dealing in high-tensile steel and other special steels.

Please feel free to contact us.

Feel free to email us.

↓↓↓

info@kumagai-steel.co.jp